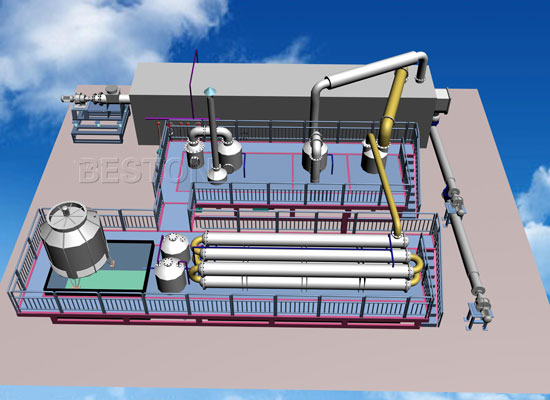

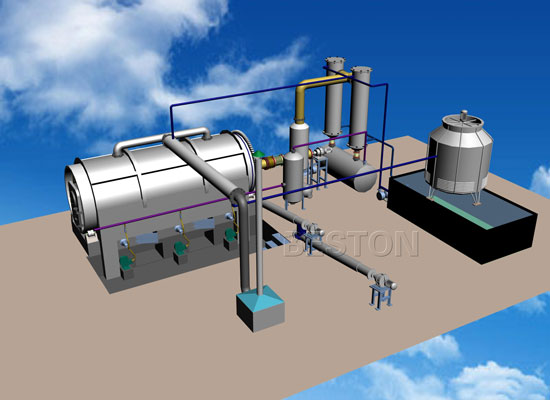

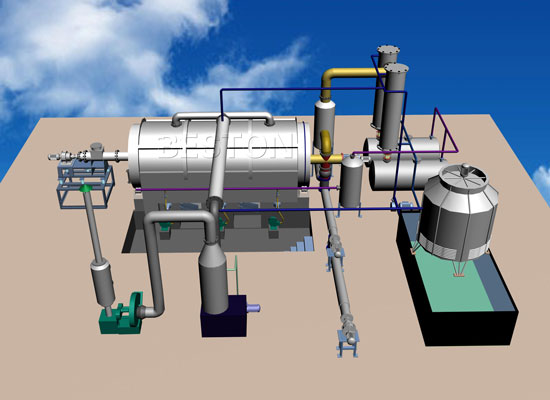

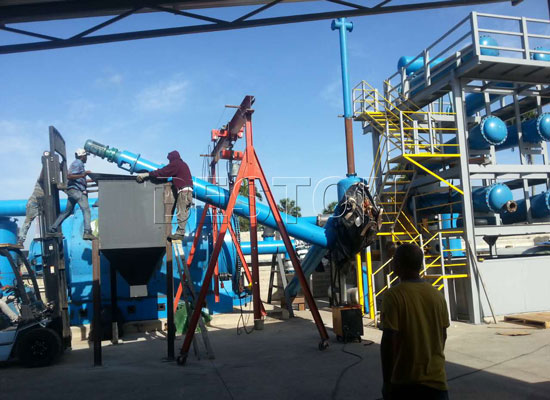

Brief Introduction of Industrial Continuous Waste Plastic Pyrolysis Production Line

Waste plastic pyrolysis production process: * The crushed mixed waste plastic is fed into the pyrolysis reactor by feeder, and initially heated in the delivery process; * The raw materials are continuously fed into the reactor and dispersed by dispersion system. The heat is provided by thermostatic heating system and the pyrolysis reaction is finished … Read more…