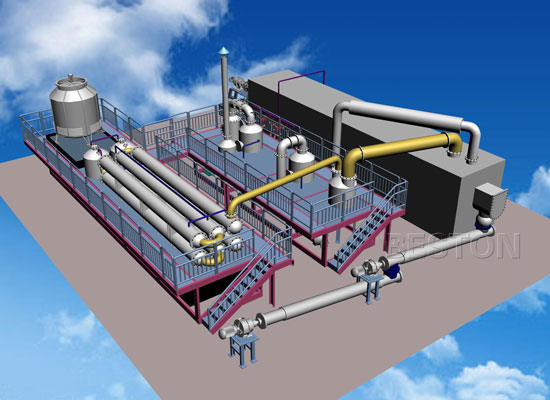

The pyrolysis of plastic to oil is a new green technology for waste plastic recycling, which can be used for turning waste plastics into fuel oil and carbon black. The fuel oil output is about 50%, which can be as a heating material used for heavy industries or distilled to diesel by oil distillation plant. The plastic to oil plant for sale also can be used for pyrolysis of waste tyre, waste rubber or medical waste. Having been in this field for 18 years, Beston Group provides high-quality products, reasonable price, and first-class after-sales service for all the customers. The waste plastic to oil plant cost is quite affordable and reasonable for the one who wants to start the pyrolysis plant busniness plan.

Our waste plastic to oil plant includes four models, BLJ-6, BLJ-10, BLJ-16, BLL-20. They have high-quality guarantee and have passed CE, ISO, SGS certificates. As there are numerous plastic pyrolysis plant manufacturers nowadays, so the users may ask, do your plants have special advantages? Our answer is, yes! Our products have adopted an innovative heating method, and the advantages of this method are as follows:

(1) When some problems occur in the system, closing the induced draught fan can cut the heating source in time to ensure the system’s safety.

(2) The heat exchange speed is 5-7 times faster than that of the traditional equipment , thus having a higher heating efficiency.

(3) Greatly extend the service life of main equipment. The new heating method can prevent the reactor being heated directly, and thus reduce its rate of depreciation. The service life of the plastic2oil equipment is 2-3 times longer than that of the old one.

Other advantages of Beston waste plastic to oil conversion plant:

1. Latest heating system, combined hot smoke heating and fire directly heating, improve heating effeciency for 20% and save energy for 15-20%.

2. New designed reactor case, with particular thermolith and asbestos cover. Increase life time and make reactor get heated uniformly.

4. Totally sealed reacting system, and slag discharging system, which prevent odor and ash releasing out.

5. Extra gas purifing system, remove chemical and impurity then recycle it into furnace for heating, clean and energy recycling.

What’s more, our plants also have many other advantages. The plastic to oil machine cost ranges from different models and operating systems. If you want to know more, please feel free to visit our factory. We will provide you high-end products and first-class service.

| Model | BLJ-6 | BLJ-10 | BLJ-16 | BLL-20 |

| Daily Capacity | 6T | 8T-10T | 15-20T | 20-24T |

| Working Method | Batch | Semi-Continuous | Fully Continuous | |

| Raw Materials | Waste Tyre, Rubber, Plastic, Oil Sludge | |||

| Reactor Size | D2.2*L6.0m | D2.6*L6.6m | D2.8*L7.1m | D1.4*L11m |

| Pattern | Horizontal & Rotary | |||

| Heating Materials | Charcoal, Wood, Fuel Oil, Natural Gas, LPG, etc. | |||

| Total Power | 24kw/h | 30kw/h | 54kw/h | 71.4kw/h |

| Floor Area (L*W*H) | 30*10*8m | 30*10*8m | 40*10*8m | 45*25*10m |

| Operating Pressure | Normal Pressure | Constant Pressure | ||

| Cooling Method | Water Cooling | |||

| Life Span | 5-8 Years | |||

Related Posts: