Waste plastic pyrolysis production process:

* The crushed mixed waste plastic is fed into the pyrolysis reactor by feeder, and initially heated in the delivery process;

* The raw materials are continuously fed into the reactor and dispersed by dispersion system. The heat is provided by thermostatic heating system and the pyrolysis reaction is finished under the action of high efficiency catalyst;

* The pyrolysis oil gas is fractionated by fractionator, and processed by fixed-bed secondary gas phase catalysis, dewaxing and other processes. Finally we get high-quality fuel oil, carbon black and a little combustible gas.

* A small amount of non-condensable gas produced in the pyrolysis process is purified by purification system, and then used as fuel for the pyrolysis system, to achieve self-heating. After purified by flue gas purification system, the flue gas is discharged.

* A small amount of solid residue is automatically and continuously discharged from the reactor after pyrolysis process. The residue can be made of fuel rods for harmless treatment.

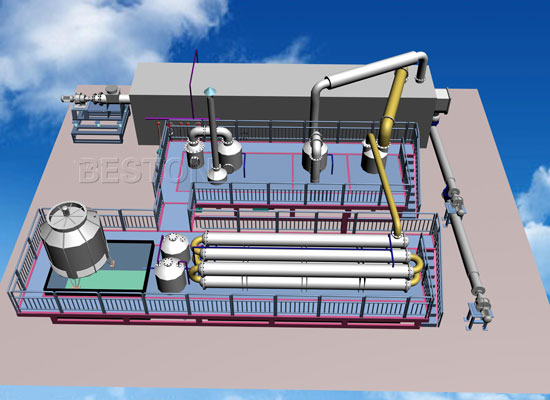

Components of plastic pyrolysis production line:

– Waste plastic pretreatment system (customer optional)

– Raw material preheating system

– Constant temperature heating system

– HCI absorption system (optional according to raw material)

– Combustible gas purification system

– Flue gas purification system

– Solid product pollution-free treatment system (customer optional)

– Control system

Features of the pyrolysis system:

1. It can realize accurate thermal dispersion of constant temperature heating;

2. The material dispersion system can greatly increase the heating area and make raw materials heated uniformly. With the use of patent structure, the system can completely solve the problem of coking;

3. After purification, the combustible gas generated by the production line is used as fuel for the heating system, and waste heat recycling technology is adopted, which has high thermal efficiency and reduces the running cost;

4. The unique and perfect HCI absirption system can avoid the huge cost of mixing waste plastic sorting;

5. It adopts two-step catalytic pyrolysis process, which has high oil yield and quality;

6. The special flue gas purification system can remove SOx, NOx and other harmful components and solid particles in the flue gas, which makes the emission indicators achieve the national requirements;

7. The whole system adopts PLC programmable logic control system, which can realize automatic control of control points, which has the functions of data acquisition, operation, recording, printing report, alarm, automatic correction and so on.