In the face of a mounting global plastic crisis, innovative solutions are not just welcome — they are essential. One such breakthrough is the transformation of waste plastics into usable fuel, a process that offers both environmental and economic benefits. This process, known as plastic pyrolysis, represents a pivotal shift in how we approach plastic waste. With the help of advanced pyrolysis technology, we are not only reducing landfill loads but also creating a new source of alternative energy.

The Plastic Waste Challenge

Plastics have become a ubiquitous part of modern life, but their convenience comes at a cost. Each year, millions of tons of plastic waste end up in landfills and oceans, taking centuries to decompose. Recycling efforts have had limited success, with many types of plastics being non-recyclable through conventional means. The global community is increasingly aware that traditional waste management strategies are insufficient, and that sustainable, circular alternatives are needed to deal with this issue effectively.

What Is Plastic Pyrolysis?

Pyrolysis is a thermochemical process that decomposes organic material at elevated temperatures in the absence of oxygen. When applied to plastic, this process breaks down long polymer chains into shorter hydrocarbons, which can be refined into fuels like diesel, gasoline, or even gas. A plastic pyrolysis plant makes this process scalable and commercially viable, enabling the conversion of large volumes of plastic waste into valuable resources.

The plastic pyrolysis process also significantly reduces greenhouse gas emissions compared to traditional incineration or landfilling. Unlike burning plastic, which releases toxic substances into the atmosphere, pyrolysis operates in a closed system that captures emissions and produces fewer pollutants.

Technological Innovation in Plastic-to-Fuel Conversion

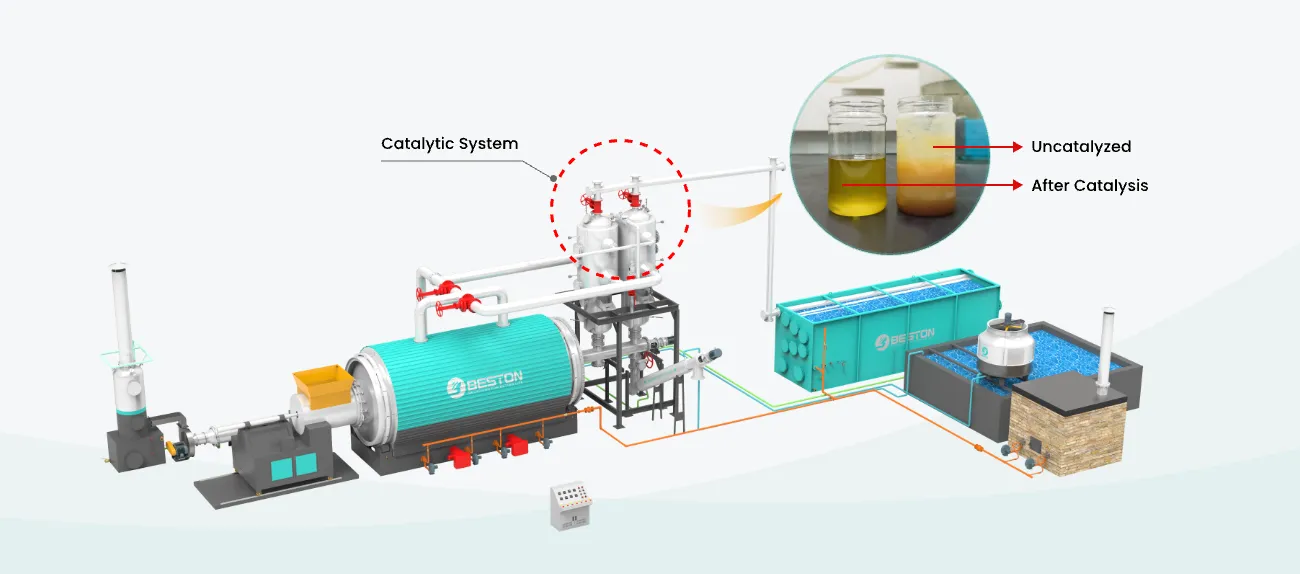

The heart of this transformation lies in sophisticated machines designed to convert plastic into usable fuel. A plastic to oil machine is engineered to handle various types of plastic waste — from household packaging to industrial scraps — and convert them efficiently into oil. The process includes feeding, pyrolysis, oil condensation, and emission control, all integrated into a seamless operation.

These machines are not only eco-friendly but also economically smart. For industries, investing in a plastic to fuel machine means turning waste disposal costs into revenue streams. The resulting fuel can be used internally to power machinery or sold as a commercial product, making it a win-win solution for both the environment and business owners.

Beston Group: Leading the Way in Sustainable Solutions

A leading name in this field is Beston Group pyrolysis. With years of experience and a commitment to innovation, Beston has developed a wide range of pyrolysis equipment that suits the needs of businesses, municipalities, and governments alike. Their machines come with cutting-edge safety systems, energy efficiency mechanisms, and customizable configurations that meet various international standards.

Beston’s plastic pyrolysis technology has been adopted globally, from Asia to Europe to Africa. By partnering with stakeholders across industries, they are helping to build a circular economy where waste is no longer a problem but a valuable input into new production cycles.

Environmental and Economic Benefits

Converting plastic to fuel brings several tangible benefits. Environmentally, it reduces landfill usage, cuts down on ocean pollution, and lowers dependence on fossil fuels. Economically, it creates jobs in the green tech sector and opens up new revenue streams for waste management companies and industries with high plastic consumption.

The fuels produced through pyrolysis can be used in generators, boilers, or even further refined for automotive use. Additionally, the process generates by-products like carbon black and combustible gas, which can be sold or reused within the system, minimizing waste and maximizing efficiency.

Conclusion: A Sustainable Path Forward

Plastic waste is a global crisis, but it also presents an opportunity for transformation. Through pyrolysis technology, we are beginning to see a future where waste becomes a resource and sustainability becomes standard. Companies like Beston Group are proving that with the right technology and vision, we can turn the tide on plastic pollution and build a greener world.

Investing in a plastic to fuel machine is not just a business decision — it’s a commitment to environmental stewardship, energy independence, and a more sustainable future.