The United Kingdom faces an ongoing challenge with plastic waste. Despite improvements in recycling systems and public awareness campaigns, millions of tonnes of plastic still end up in landfills or incinerators every year. However, a promising technological innovation is reshaping the conversation — plastic pyrolysis. This process, which converts waste plastic into usable fuels, could be the cornerstone of a more sustainable and circular economy.

Understanding the Science Behind Plastic Pyrolysis

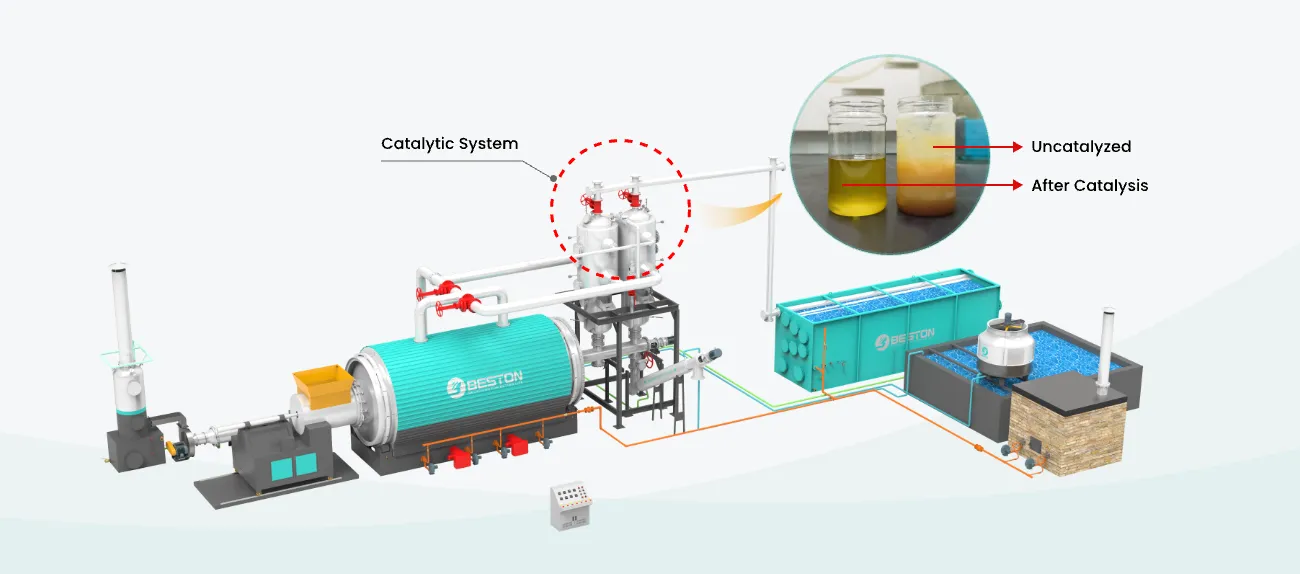

Plastic pyrolysis is a thermochemical process that breaks down plastic waste into smaller molecules in the absence of oxygen. When plastic is heated in a controlled environment, it decomposes into valuable products such as oil, gas, and carbon black. These outputs can then be refined or reused, effectively turning waste into a renewable energy source.

A Beston pyrolysis plant exemplifies how advanced engineering and sustainability can coexist. Such systems are designed to maximize fuel yield and minimize emissions, offering both environmental and economic benefits. Unlike incineration, which releases carbon dioxide and toxic gases, pyrolysis operates in a closed system that captures and reuses energy efficiently.

Why the UK Is Embracing Pyrolysis Technology

In recent years, there has been growing interest in establishing more pyrolysis plants in the UK. The government’s focus on net-zero emissions and renewable energy targets has created an ideal environment for innovative waste-to-energy technologies.

Local councils and private companies are collaborating to reduce plastic waste dependency on traditional recycling, which is limited by contamination and fluctuating market demand. Pyrolysis bridges that gap, converting non-recyclable plastics into valuable resources such as synthetic diesel or kerosene, which can power vehicles, generators, and industrial equipment.

Economic and Environmental Advantages

The benefits of adopting pyrolysis are multifaceted. First, it helps reduce landfill usage and the environmental impact of incineration. Second, the fuel produced can offset fossil fuel consumption, reducing greenhouse gas emissions. Third, pyrolysis supports local economies by creating jobs in waste collection, plant operation, and fuel distribution.

A high-quality plastic to fuel machine for sale offers a reliable and scalable solution for businesses and municipalities alike. These machines can process various types of plastics, including polyethylene, polypropylene, and polystyrene, transforming them into useful energy products. The result is a sustainable business model that converts waste into profit.

Technological Innovation and Safety Standards

Modern plastic pyrolysis machine designs integrate safety and automation features that make them more efficient than ever. With temperature control systems, gas purification units, and automated feeding mechanisms, today’s pyrolysis plants require minimal human intervention.

The UK’s emphasis on environmental compliance also ensures that any new installations adhere to strict emission standards. Companies like Beston are leading this transition by offering equipment that meets international certifications while maintaining cost-effectiveness.

The Road for Sustainable Fuel Production

The success of plastic pyrolysis in the UK will depend on three key factors: technological innovation, policy support, and public acceptance. By investing in research and development, improving infrastructure, and educating the public about the benefits of this process, the country can lead the global transition toward a cleaner energy future.

In time, plastic waste may no longer be seen as an environmental burden but rather as a valuable resource. Companies that adopt advanced pyrolysis systems today will be at the forefront of this new industrial revolution, turning pollution into power.

Conclusion

Plastic pyrolysis represents a bridge between environmental responsibility and economic opportunity. The UK’s proactive stance on sustainability makes it a prime candidate for large-scale adoption of this technology. Whether through municipal initiatives or private-sector investments, converting plastic to fuel offers a path toward cleaner cities and a greener future.

With innovative equipment from providers like Beston, the dream of transforming waste into energy is becoming a tangible reality. The combination of science, sustainability, and smart policy could soon redefine how the UK — and the world — views plastic waste.