Major Features of the Latest Series

1. The waste pyrolysis equipment does comprehensive treatment with waste plastics, and can generate carbon black and plastic oil at the same time.

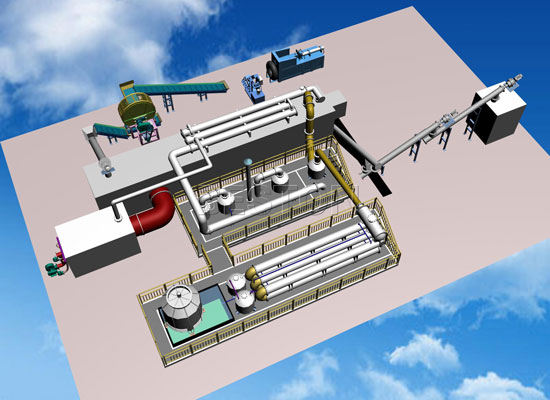

2. Each equipment consists of the following systems:

a. Horizontal rotating pyrolysis reactor.

b. Combination of manifold and packed tower.

c. Pressure, temperature sensing system.

d. Central electronic control system.

e. Three-dimensional exhaust pipe cooling system with damping device.

f. Gas heating system (exhaust gas disposal system).

g. Adopting powerful desulfurization and dust removal system.

h. Equipped with reactor rotary speed control device and cleanup calandria device.

2. National Initiative

a. In the key device, rector’s design, it completely overcomes the disadvantages factors of the current vertical flat pyrolysis reactor, such as uneven heating, tended to break, low yield, short service life, etc. Our reactor adopts horizontal double drive rotating structure and can guarantee 6-60 turn per minute.

b. Rapid and practical feeding and discharging systems.

c. High-efficiency gas heating system. In the pyrolysis process, when the heated gas reaches 150℃, it will generate a large number of gas that can’t be liquefied in the normal pressure and temperature – methane to butane. After being sufficiently burnt by the specially-designed gas nozzle, the gas generates a large number of energy, which can save energy sources greatly. Taking coal as an example, it needs 1.5t coal every 24 hours without using combustion-supporting fuel gas, while after using combustion-supporting fuel gas, it only needs 0.5t coal every 24 hours. It can greatly improve production and economic benefits.

d. The flue dust removal system has TLC-I (certified). It is equipped with two-way water impact type cyclone dust chamber, which can ensure the discharge of flue outlet to meet the national emission standards.