Proper disposal of used tires is essential because this kind of waste materials has seriously polluted our environment. Compared with landfill and burning, recycling used tyres into useful resources is a better and meaningful method.

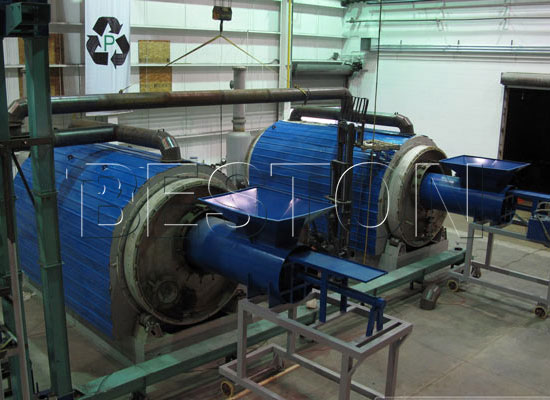

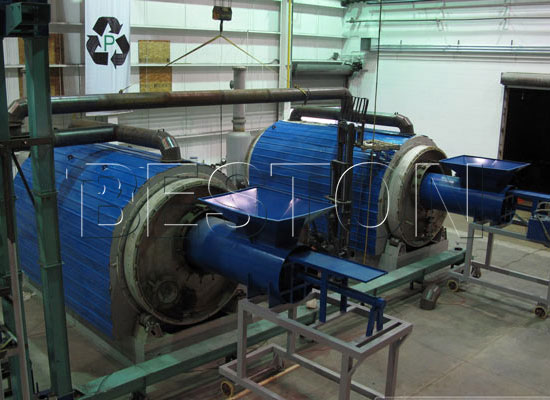

As a leading manufacturer of environmental protection equipment in China, Beston manufactures and supplies used tire recycling equipment which has features of safety, energy saving and environmental protection. Through our equipment, waste tires can be effectively turned into fuel oil, carbon black and steel wire, all of which have a wide range of applications.

For example, the tire oil can be widely used as fuel oil in industries such as steel and iron and boiler factories, ceramics, power or chemical industries etc., or used for generators to get electricity. Carbon black can be used for making construction bricks with clay, or used as fuel. Steel wire can be sold directly or recycled to produce new steel products.

The security designs of the plant:

1.The main components of the exhaust gas that cannot be condensed to oil are alkanes, which are dangerous if burned directly. The hydroseal can remove their sulfur, impurities and then the clean gas can be recycled to the burning room to be used as fuel. Besides, the hydroseal can also stop the gas burning back.

2. It is equipped with automatic welding machine, which can not only greatly improve working efficiency, but also guarantee the welding quality.

3. Professional thermometer and pressure gauge to inspect temperature and pressure at any time.

4. The latest heating method which combines the advantages of direct and indirect heating can prolong the service life of the reactor for 5-8 years.

5. In the daily operation, the exhaust gas room is closed. If the pressure is too high, you can open the door of the exhaust gas room and the combustion gas can be burned directly, which can quickly reduce the temperature and pressure in the reactor.

To meet the different demands of customers, we provide six models of used tire recycling equipment for sale, such as BLJ-06, BLJ-10, BLL-16, BLL-30, BLL-40 and BLL-50. If you have special requirement, we can also provide you with the customized equipment.

| Item | Details | |||||

| Model | BLJ-6 | BLJ-10 | BLL-16 | BLL-30 | BLL-40 | BLL-50 |

| Daily capacity | 6T | 10T | 20T | 30T | 40T | 50T |

| Working method | Batch | Semi-continuous | Fully continuous | |||

| Raw materials | Waste tire, plastic, rubber, oil sludge, medical waste | |||||

| Reactor size | D2.2*L 5.1m | D2.8*L6.2 m | D2.8 *L7.1 m | L12.5*W2.2*H2.5m | ||

| Pattern | Horizontal & rotary | Not rotary type | ||||

| Heating materials | Charcoal, wood, fuel oil, natural gas, LPG, etc. | |||||

| Total power | 24 kw/h | 30 kw/h | 54 kw/h | 53.6kw/h | 62kw/h | 84kw/h |

| Floor area (L*W*H) | 20*10*10 m | 25*15*10 m | 25*15*10 m | 20*15*10m | 33*15*10m | 33*15*10m |

| Operating pressure | Normal pressure | Constant pressure | ||||

| Cooling method | Water cooling | |||||

| Service life | 5-8 years | |||||

Our After-sales Service:

1. Design the installation drawings according to your site.

2. 1 year warranty, engineers available to service at any time.

3. Periodical call visit, to make sure there is no problems of the equipment.

4. Design specific maintenance program according to different situation of your plant.

5. For each set of machine, one technician will be sent to guide your installation, test the machine and train your workers. Besides, we will provide one month’s service for free.