Among so many tire recycling plant suppliers, why could Beston Machinery stand out and become a leader? Now I will simply address the advantages of our tire recycling plant for sale and you will find the answer easily.

1. The plant adopts advanced technology, which can generate useful resources from waste tires.

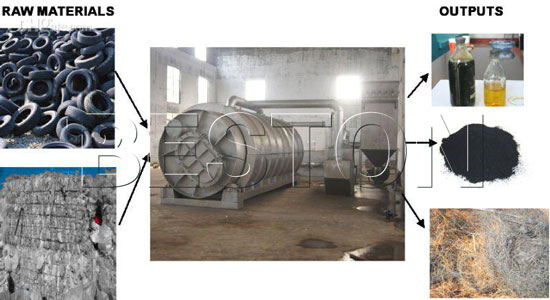

Utilizing advanced pyrolysis technology, our waste tire recycling plant can effectively convert waste tires into tire oil, carbon black and steel wire. All of the products have a wide range of applications. The oil can be used as industrial fuel materials for burning, or further refined to diesel or gasoline. The carbon black can be used for making construction bricks with clay or used as fuel. The steel wire can be re-sale or reprocessed.

2. The plant is equipped with mature devices, which can guarantee the plant is safe, energy-saving, pollution-free and high-efficiency.

Firstly, our waste tyre recycling plant for sale is equipped with safety device (alarm for over temperature and pressure, auto pressure releasing system, extra gas recycling system, fire fighting devices), which can avoid danger in the production process and guarantee safety.

Secondly, there is also a little combustible gas produced in the process. The gas can be recycled to heat the reactor as fuel, which will save energy for the whole working process.

Thirdly, in the dedusting system, three steps (water washing, ceramic ring adsorption, water spray) are used to dedust the hot smoke from reactor, and more than 95% of the dust would be removed. The released gas is pollution-free and can be discharged in the air directly.

Fourthly, the structure of reactor for the pyrolysis process is 360-degree rotating. This special design makes the bottom of reactor heat evenly, which lengthen the service life of reactor as well as improve the pyrolysis speed.

3. The plant has special methods that can improve the oil yield efficiency.

Firstly, compared with the general condensers, our tubular condenser has the features of larger cooling area and better cooling effect, which can can further ensure and improve the oil yield efficiency.

Secondly, we can provide you with special catalyst, which can not only improve the flavor and color of the oil, but also accelerate the reaction speed. Thus, it can increase the average oil output by 5%.

4. The plant provides various types available for your choice, which can meet different customers’ demand.

For the waste tyre recycling plant, we have three operating systems (batch, semi-continuous and fully continuous) and six models available for you to choose. Their handling capacities range from 6t/d to 50t/d. If you have other special requirements, we can also customize the plant for you.

| Item | Details | |||||

| Model | BLJ-6 | BLJ-10 | BLL-16 | BLL-30 | BLL-40 | BLL-50 |

| Daily capacity | 6T | 10T | 20T | 30T | 40T | 50T |

| Working method | Batch | Semi-continuous | Fully continuous | |||

| Raw materials | Waste tire, plastic, rubber, oil sludge, medical waste | |||||

| Reactor size | D2.2*L 5.1m | D2.8*L6.2 m | D2.8 *L7.1 m | L12.5*W2.2*H2.5m | ||

| Pattern | Horizontal & rotary | Not rotary type | ||||

| Heating materials | Charcoal, wood, fuel oil, natural gas, LPG, etc. | |||||

| Total power | 24 kw/h | 30 kw/h | 54 kw/h | 53.6kw/h | 62kw/h | 84kw/h |

| Floor area (L*W*H) | 20*10*10 m | 25*15*10 m | 25*15*10 m | 20*15*10m | 33*15*10m | 33*15*10m |

| Operating pressure | Normal pressure | Constant pressure | ||||

| Cooling method | Water cooling | |||||

| Service life | 5-8 years | |||||