Our tyre recycling plants have been exported to more than 20 countries. Taking the tyre recycling plant in Pakistan for example, today I will introduce this plant in detail.

Our tyre recycling plant in Pakistan is popular for its amazing conversion. The plant applies pyrolysis technology, which helps finishing the process of converting tyres into useful resources. In the pyrolysis process, tyre oil, carbon black and steel wire will be produced. The oil can be used as industrial fuel materials for burning, or further refined to diesel or gasoline. The carbon black can be used for making construction bricks with clay or used as fuel. The steel wire can be re-sale or reprocessing. All of the three end products are in high demand and have high prices in Pakistan market. There is also a little combustible gas produced in the process, the gas can be recycled to heat the reactor as fuel, which will save energy for the whole working process.

The tire recycling plant in Pakistan has these advantages below:

1. The plant is equipped with advanced safety device and dedusting system, which can guarantee safety and no pollution in production process.

2. With 17 years’ experience in the field of tyre recycling, our plant has the latest technology, which can increase oil yield by 5% and save energy consumption by 30% than the general machines.

3. The reactor adopts Q245R/Q345R special plate, which can lengthen its service life. The service life of the plant can reach 5-8 years and it will save much cost for you.

4. As one of the most professional tyre recycling plant suppliers in China, we can promise you high-quality products and first-class service. We have consultant service 24 online. Don’t hesitate to consult us all about the plant at any time.

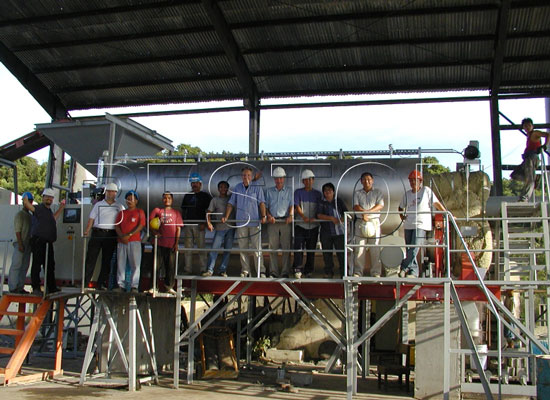

Besiedes the tyre recycling plant in pakistan, we also have exported our plant to many countries, such as Brazil, Jordan, Nigeria etc. This is a case in Brazil:

| Model | BLJ-6 | BLJ-10 | BLJ-16 | BLL-20 |

| Daily Capacity | 6T | 8T-10T | 15-20T | 20-24T |

| Working Method | Batch | Semi-Continuous | Fully Continuous | |

| Raw Materials | Waste Tyre, Rubber, Plastic, Oil Sludge | |||

| Reactor Size | D2.2*L6.0m | D2.6*L6.6m | D2.8*L7.1m | D1.4*L11m |

| Pattern | Horizontal & Rotary | |||

| Heating Materials | Charcoal, Wood, Fuel Oil, Natural Gas, LPG, etc. | |||

| Total Power | 24kw/h | 30kw/h | 54kw/h | 71.4kw/h |

| Floor Area (L*W*H) | 30*10*8m | 30*10*8m | 40*10*8m | 45*25*10m |

| Operating Pressure | Normal Pressure | Constant Pressure | ||

| Cooling Method | Water Cooling | |||

| Life Span | 5-8 Years | |||

Our After-sales Service

1. Design the installation drawings according to your site.

2. 1 year warranty, engineers available to service at any time.

3. Periodical call visit, to make sure there is no problems of the equipment.

4. Design specific maintenance program according to different situation of your plant.

5. For each set of machine, one technician will be sent to guide your installation, test the machine and train your workers. Besides, we will provide one month’s service for free.