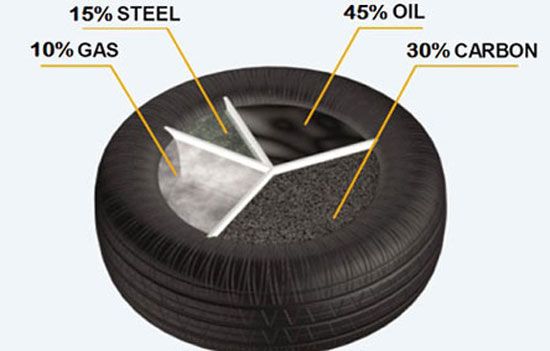

The scrap tyre recycling plant adopts the advancd pyrolysis technology, so it is also called scrap tyre pyrolysis plant. This plant is used for converting scrap tyres into resources that we need, such as tyre oil, carbon black and steel wire.

This plant mainly includes batch operating plant, semi automatic operating plant and fully automatic operating plant. The batch type doesn’t need pre-treatment devices and it disposes oil sludge by batch. The semi-automatic type can work for 3-4 shifts per day and then its reactor needs about 1 hour to cool down. The fully automatic type can work continuously for 24 hours per day without a stop. Each set of plant is equipped with extra gas recycling system and dedusting system. The gas recycling system can take full advantage of the exhaust gas generated in the process, which is energy saving. And the dedusting system has guaranteed no pollution to the air.

Our scrap tyre recycling plants are in line with the concept of environment protection today. are in line with the concept of environment protection today. Welcome to visit our factory and we hope to establish a good relationship with you. It’s high time for us to do something to protect our invironment.

| Item | Details | |||||

| Model | BLJ-6 | BLJ-10 | BLL-16 | BLL-30 | BLL-40 | BLL-50 |

| Daily capacity | 6T | 10T | 20T | 30T | 40T | 50T |

| Working method | Batch | Semi-continuous | Fully continuous | |||

| Raw materials | Waste tire, plastic, rubber, oil sludge, medical waste | |||||

| Reactor size | D2.2*L 5.1m | D2.8*L6.2 m | D2.8 *L7.1 m | L12.5*W2.2*H2.5m | ||

| Pattern | Horizontal & rotary | Not rotary type | ||||

| Heating materials | Charcoal, wood, fuel oil, natural gas, LPG, etc. | |||||

| Total power | 24 kw/h | 30 kw/h | 54 kw/h | 53.6kw/h | 62kw/h | 84kw/h |

| Floor area (L*W*H) | 20*10*10 m | 25*15*10 m | 25*15*10 m | 20*15*10m | 33*15*10m | 33*15*10m |

| Operating pressure | Normal pressure | Constant pressure | ||||

| Cooling method | Water cooling | |||||

| Service life | 5-8 years | |||||