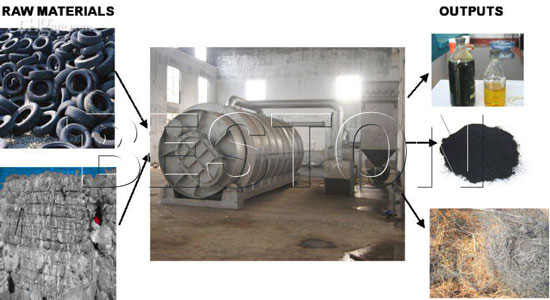

The tyre to fuel recycling plant is also called waste tyre pyrolysis plant. It has adopted the latest pyrolysis technology. Through this technology, our plant is capable of converting waste tyre to fuel oil, carbon black as well as steel wire.

As a leading domestic manufacturer, we can promise you that there are many advantages in our tyre to fuel recycling plants.

In the first place, the pyrolysis technology is the effort of our engineers after 17 years’ research and development. This is a green technology and the whole pyrolysis process is very environment friendly.

Secondly, our plant is more effective and profitable. The fuel oil can be widely used in industries such as steel, iron and boiler factories, ceramics, power or chemical industries or hotels, restaurants etc., or used for generators to get electricity. The carbon black can be used for construction bricks with clay or used as fuel. The steel wire can be recycled to the steel plants to produce new steel products. You will surely benefit a lot from these final products and get you investment back very soon.

Thirdly, our plant is equipped with the extra gas recycling system. The waste tyres in the reactor under high temperature will produce gas. If filtered directly, it will be a waste of resources. So our system can collect the extra gas and filter them after the secondary burning, thus saving fuel cost for users.

Fourthly, our plant adopts the most advanced dedusting system domestically. When the whole working process is completed, the gas will be pollution-free and can be discharged to the air directly. Therefore, users do not need to worry about the secondary pollution problem any more.

Our plants will help you make the most profit with reasonable price and relatively low cost. For more details about our plants, please feel free to contact us at any time.

| Item | Details | |||||

| Model | BLJ-6 | BLJ-10 | BLL-16 | BLL-30 | BLL-40 | BLL-50 |

| Daily capacity | 6T | 10T | 20T | 30T | 40T | 50T |

| Working method | Batch | Semi-continuous | Fully continuous | |||

| Raw materials | Waste tire, plastic, rubber, oil sludge, medical waste | |||||

| Reactor size | D2.2*L 5.1m | D2.8*L6.2 m | D2.8 *L7.1 m | L12.5*W2.2*H2.5m | ||

| Pattern | Horizontal & rotary | Not rotary type | ||||

| Heating materials | Charcoal, wood, fuel oil, natural gas, LPG, etc. | |||||

| Total power | 24 kw/h | 30 kw/h | 54 kw/h | 53.6kw/h | 62kw/h | 84kw/h |

| Floor area (L*W*H) | 20*10*10 m | 25*15*10 m | 25*15*10 m | 20*15*10m | 33*15*10m | 33*15*10m |

| Operating pressure | Normal pressure | Constant pressure | ||||

| Cooling method | Water cooling | |||||

| Service life | 5-8 years | |||||