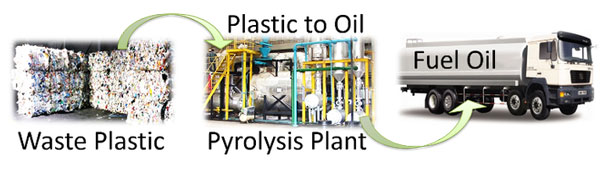

Our company is specializing in manufacturing waste plastic pyrolysis plant which is used to recycle plastic to oil and carbon black. So far, our plants have been well received by our domestic and foreign customers because the plastic to oil process of our plant is proved to be zero emission and high efficiency.

Waste plastic to oil process description:

1.Firstly, the raw material-waste plastics will be put into the reactor.

2. Secondly, burn the fuel material (coal, wood, oil or natural gas) in the combustion system. The reactor will slowly heat, when the temperature reach around 120℃, it will produce oil gas.

3. Oil gas will be processed and then go to oil condenser system to be liquefied. The gas which can not be liquefied under normal pressure will go back to combustion system to replace the fuel materials to burn the reactor.

4. After finished oil production, the temperature of reactor will be down, at the same time, carbon black will be discharged.

5. Lastly, the smoke can achieve national emission standard through the dedusting system and can be discharged in the air directly.

If you are thinking about investing in plastic recycling industry, our plant will be your best choice. Warmly welcome to join us and we here highly appreciate the previous opportunity to cooperate with you.

1 thought on “Plastic to Oil Process”

Comments are closed.