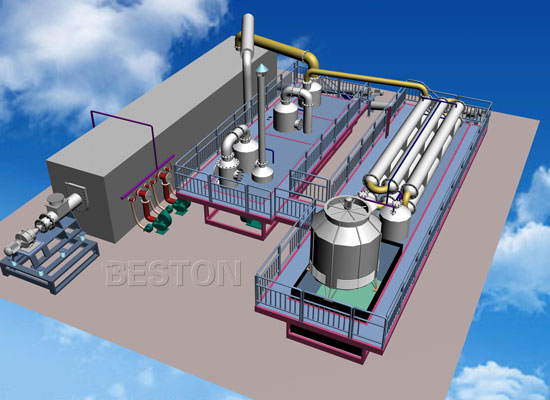

With 18 years of experience in the field of tyre pyrolysis and continuous research and improvement, Beston provides waste tyre oil plant which has reached a high level in technology. Here, I will give you a clear description of our product.

It adopts the new green pyrolysis technology. Through the use of the plant, waste tyres can be effectively converted to pyrolysis oil, carbon black and steel wire. The oil from tyres plant can be widely used as fuel oil in industries such as steel and iron and boiler factories, ceramics, power or chemical industries etc. And it can be used for generators to get electricity. Carbon black can be used for making construction bricks with clay, also can be used as fuel. Steel wire can be recycled into smelting plant.

Besides, it is equipped with mature safety devices (thermometer, pressure gauge, safety valve and electric control system) and advanced dedusting system (water spray, ceramic ring filter, washing chamber), which can guarantee the whole process is safe, energy-saving and environmental protection.

The tyre oil plants include batch operating plant, semi-automatic operating plant and fully automatic operating plant. The batch type doesn’t need pre-treatment devices and it disposes oil sludge by batch. The semi-automatic type can work for 3-4 shifts per day and then its reactor needs about 1 hour to cool down. The fully automatic type can work continuously for 24 hours per day without a stop. Each set of plant is guaranteed in best quality and the most reasonable price.

For each set of tyre to oil plant, one technician will be sent to guide your installation, test the machine and train your workers until you can run the plant smoothly. Besides, we will provide on-year warranty and our engineers are available to serve at any time.

| Item | Details | |||||

| Model | BLJ-6 | BLJ-10 | BLL-16 | BLL-30 | BLL-40 | BLL-50 |

| Daily capacity | 6T | 10T | 20T | 30T | 40T | 50T |

| Working method | Batch | Semi-continuous | Fully continuous | |||

| Raw materials | Waste tire, plastic, rubber, oil sludge, medical waste | |||||

| Reactor size | D2.2*L 5.1m | D2.8*L6.2 m | D2.8 *L7.1 m | L12.5*W2.2*H2.5m | ||

| Pattern | Horizontal & rotary | Not rotary type | ||||

| Heating materials | Charcoal, wood, fuel oil, natural gas, LPG, etc. | |||||

| Total power | 24 kw/h | 30 kw/h | 54 kw/h | 53.6kw/h | 62kw/h | 84kw/h |

| Floor area (L*W*H) | 20*10*10 m | 25*15*10 m | 25*15*10 m | 20*15*10m | 33*15*10m | 33*15*10m |

| Operating pressure | Normal pressure | Constant pressure | ||||

| Cooling method | Water cooling | |||||

| Service life | 5-8 years | |||||