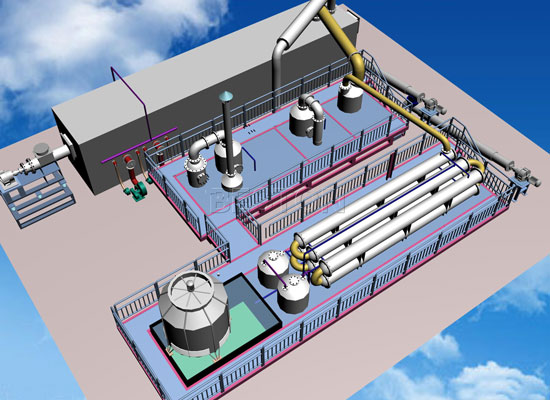

With the increasing number of waste plastics, our plastic pyrolysis plants have become more and more popular. In order to meet different customers’ demands, we have manufactured our plants in six models, BLJ-06, BLJ-10, BLJ-16, BLL-20. BLJ-06 and BLJ-10 are batch operating systems; BLJ-16 is semi-continuous system; BLL-20 is fully continuous system.

The continuous plastic pyrolysis plant is designed on the basis of batch systems and semi-continuous systems. Compared with them, the fully continuous operating systems have the following unique features.

1. The continuous waste plastic recycling machine has relatively larger processing capacities of 30-50mt per day.

2. The fully continuous plant can achieve feeding of materials and discharging of slags automatically, and can also finish the two steps at the same time, which not only saves time, but also saves fuels.

3. The reactor of our auto operating pyrolysis plant for sale is stable and not rotary, which makes the temperature rise and pyrolysis react quickly. This special design makes the whole pyrolysis process efficient and can also save much heating materials.

5. Before pyrolysis, the tyres and plastics need to be cut into small pieces. For plastic waste, if the materials’ humidity is higher than 15%, it also a dryer to dispose the waste first. This pre-treatment step can make the pyrolysis process more efficient.

6. The continuous plant can run for 24 hours a day without a stop and needn’t to be cooled before the second batch.

7. Continuous waste plastic pyrolysis plant adopts new type of condensers which has larger cooling area and better cooling effect.In addition, we can provide special catalyst, which is made from 24 chemicals. The catalyst can not only reduce sulfur content and density of oil, but also improve its flavor and color.

| Model | BLL-20 |

| Daily Capacity | 20-24T |

| Working Method | Fully Continuous |

| Raw Materials | Waste Tyre, Rubber, Plastic, Oil Sludge |

| Reactor Size | D1.4*L11m |

| Pattern | Horizontal & Rotary |

| Heating Materials | Charcoal, Wood, Fuel Oil, Natural Gas, LPG, etc. |

| Total Power | 71.4kw/h |

| Floor Area (L*W*H) | 45*25*10m |

| Operating Pressure | Constant Pressure |

| Cooling Method | Water Cooling |

| Life Span | 5-8 Years |

Beston Service:

Please do NOT assume we are limited to manufacture and sell machines, to perform the idea of “Engineering For Tomorrow’s World”, in the whole world, Beston also provide the below service:

1. Related project technology and cost consulting.

2. Related products testing and making certification.

3. Products upgrading, Parts/Quick-Wear Parts/Catalyst supplying, Team training, Project agent running.

4. Turnkey Projects and Value-added Service.

5. Joint venture.

1 thought on “Continuous Plastic Pyrolysis Plant”

Comments are closed.