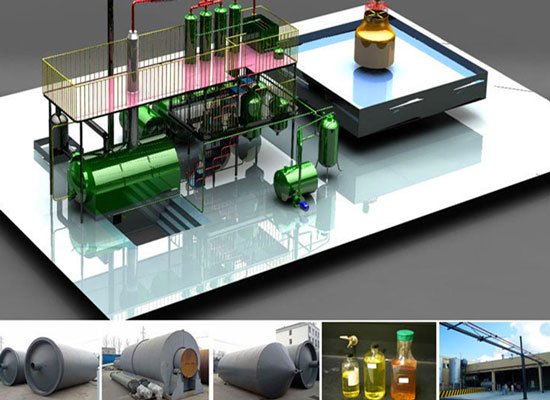

The pyrolysis oil plant supplied by Beston, the most professional manufacturer in this field in China, is the high-tech machinery for waste plastic recycling. Compared with landfill and burning, the plant can recycle waste plastics into useful resources in an environmental manner.

The following is the simplified description of plastic pyrolysis process:

1. Put the plastics into the reactor.

2. Heat the reactor by using fuel materials, such as coal, charcoal, fuel gas, wood etc. The reactor will be slowly heated, when the temperature reaches around 250 degrees, the oil gas will be produced.

3. A part of oil gas will go to the condensing system to be liquid oil. The gas which can not be liquefied under normal pressure will go back to combustion system. It can replace the fuel material to heat the reactor, which will save energy for the whole pyrolysis process.

4. After finishing oil production, the temperature of the reactor will be down. At the same time, the carbon black will be discharged automatically.

5. Lastly, the smoke produced from reactor can achieve national emission standard after being processed by the dedusting system.

6. The reactor must be cooled before starting another batch working.

When the whole plastic pyrolysis oil process is over, we can get pyrolysis oil and carbon black. The pyrolysis oil can be widely used as fuel oil in industries such as steel and iron and boiler factories, ceramics, power or chemical industries etc. And it can also be used for generators to get electricity. Carbon black can be used for making construction bricks with clay, also can be used as fuel.

If you want to know more details about our plants, please feel free to contact us. We will reply you within 24 hours.

| Model | BLJ-6 | BLJ-10 | BLJ-16 | BLL-20 |

| Daily Capacity | 6T | 8T-10T | 15-20T | 20-24T |

| Working Method | Batch | Semi-Continuous | Fully Continuous | |

| Raw Materials | Waste Tyre, Rubber, Plastic, Oil Sludge | |||

| Reactor Size | D2.2*L6.0m | D2.6*L6.6m | D2.8*L7.1m | D1.4*L11m |

| Pattern | Horizontal & Rotary | |||

| Heating Materials | Charcoal, Wood, Fuel Oil, Natural Gas, LPG, etc. | |||

| Total Power | 24kw/h | 30kw/h | 54kw/h | 71.4kw/h |

| Floor Area (L*W*H) | 30*10*8m | 30*10*8m | 40*10*8m | 45*25*10m |

| Operating Pressure | Normal Pressure | Constant Pressure | ||

| Cooling Method | Water Cooling | |||

| Life Span | 5-8 Years | |||