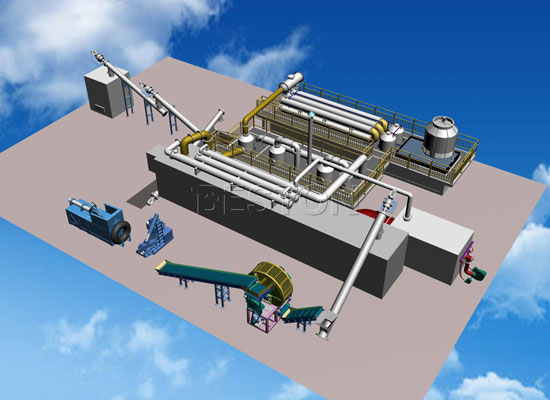

For the customers who want to make the waste tire pyrolysis recycling machine operate automatically, save more manpower and handle more raw materials in per day, the full automatic continuous operating pyrolysis machine is the best choice.

With a large capacity 30-50t/d, our full automatic waste tire recycling machine refers to converting waste tires into fuel oil by using high temperature heating. This advanced process is called pyrolysis. Besides fuel oil, we can also get carbon black and steel wire from the waste tires through pyrolysis process. All the end products can sell directly and they have wide applications, high value and fetch good prices in the market.

The Attractive Characteristics of the Automatic Waste Tire Recycling Machine:

1. The automatic recycling machine can achieve feeding of materials and discharging of slags automatically, and can also finish the two steps at the same time, which not only saves time, but also saves fuels.

2. The reactor of our auto operating pyrolysis plant is stable and not rotary, which makes the temperature rise and pyrolysis react quickly. This special design makes the whole pyrolysis process efficient and can also save much heating materials.

3. The plant is equipped with safety device (alarm for over temperature and pressure, auto pressure releasing system, extra gas recycling system, fire fighting devices) and advanced dedusting system (water washing, water spray, ceramic ring adsorption and activated carbon adsorption), which will guarantee safety and no pollution in production.

4. Before pyrolysis, the tyres need to be cut into small pieces. This pre-treatment step can make the pyrolysis process more efficient.

5. The automatic waste tire recycling machine can run for 24 hours a day without a stop and needn’t to be cooled before the second batch.

6. Our automatic tire recycling machine adopts new type of condensers which has larger cooling area and better cooling effect. In addition, we can provide special catalyst, which is made from 24 chemicals. The catalyst can not only reduce sulfur content and density of oil, but also improve its flavor and color.

| Model | BLL-20 |

| Daily Capacity | 20-24T |

| Working Method | Fully Continuous |

| Raw Materials | Waste Tyre, Rubber, Plastic, Oil Sludge |

| Reactor Size | D1.4*L11m |

| Pattern | Horizontal & Rotary |

| Heating Materials | Charcoal, Wood, Fuel Oil, Natural Gas, LPG, etc. |

| Total Power | 71.4kw/h |

| Floor Area (L*W*H) | 45*25*10m |

| Operating Pressure | Constant Pressure |

| Cooling Method | Water Cooling |

| Life Span | 5-8 Years |