As a professional plastic recycling plant manufacturer in China, Beston Group has been specialized in this field since 1998, and now we have the most advanced plastic recycling plant for sale with high-quality and reasonable price.

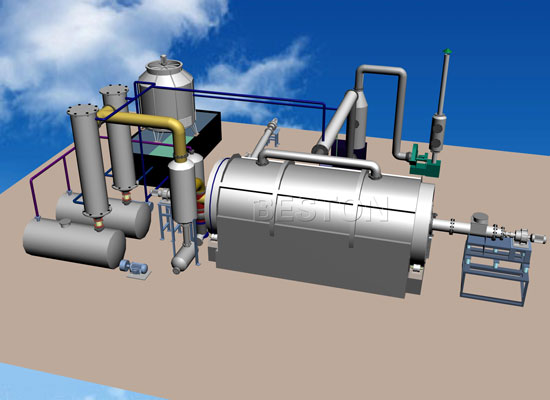

The plastic recycling plant adopts an advanced technology called pyrolysis, which can effectively convert waste plastic into plastic oil and carbon black. Both of the end-products are useful resources and have wide applications. The oil can be used as industrial fuel materials for burning, or further refined to diesel or gasoline. The carbon black can be used for construction bricks with clay or used as fuel. They are both in high demand and sell well in the market.

Utilizing pyrolysis technology to recycle waste plastics, what we are mostly concerned about is the oil yield. Generally, there are three factors that affect the oil output rate. Firstly, different materials have different oil output rates. For example, PE has 80-85% oil output rate, which is the highest rate. While ABS only has 40%. Secondly, the rate also differs according to the materials’ humidity. For example, wet leftovers of paper have 15-20% oil output rate, while dry leftovers of paper have 60%. Moreover, the operating systems also influence the oil output. For our waste plastic recycling plants, we have three operating systems, including batching system, semi-continuous system and continuous system. Compared with batching system, the continuous systems have higher oil yield and higher efficiency.

Higher oil yield means higher profits. Having known the important factors which influence the oil yield, we must take steps to improve the oil yield. With 17 years’ experience in plastic recycling, Beston Machinery has two important methods to improve the oil yield.

Secondly, we can provide you with special catalyst, which can not only improve the flavor and color of the oil, but also accelerate the reaction speed. Thus, it can increase the average oil output by 5%.

Besides producing useful end-products and having higher oil yield efficiency, our plant also has the features of safe, energy-saving and environmental protection. After having learned about the advantages and features of the plant, you will find the plastic recycling plant price is also quite reasonable. Get your free quotation now!

| Item | Details | |||||

| Model | BLJ-6 | BLJ-10 | BLL-16 | BLL-30 | BLL-40 | BLL-50 |

| Daily capacity | 6T | 10T | 20T | 30T | 40T | 50T |

| Working method | Batch | Semi-continuous | Fully continuous | |||

| Raw materials | Waste tire, plastic, rubber, oil sludge, medical waste | |||||

| Reactor size | D2.2*L 5.1m | D2.8*L6.2 m | D2.8 *L7.1 m | L12.5*W2.2*H2.5m | ||

| Pattern | Horizontal & rotary | Not rotary type | ||||

| Heating materials | Charcoal, wood, fuel oil, natural gas, LPG, etc. | |||||

| Total power | 24 kw/h | 30 kw/h | 54 kw/h | 53.6kw/h | 62kw/h | 84kw/h |

| Floor area (L*W*H) | 20*10*10 m | 25*15*10 m | 25*15*10 m | 20*15*10m | 33*15*10m | 33*15*10m |

| Operating pressure | Normal pressure | Constant pressure | ||||

| Cooling method | Water cooling | |||||

| Service life | 5-8 years | |||||